Bulk Process Equipment, Bulk Solid Material Processing & Handling Equipment, Industrial Bulk Solids Material Handling Systems

|

Material Handling & Processing Equipment |

About Us | Material Handling Equipment | Solid Material Processing | Plant Services | Manufacturers | Equipment Photos | Clients | Case Studies | News | Contact Us | Home

Case Studies: Bulk Material Handling Equipment & Systems

Success Stories for I-2/BPST Customers

Case Study 1 • Case Study 2 • Case Study 3 • Case Study 4 • Case Study 5 • Case Study 6

Case Study 7 • Case Study 8 • Case Study 9 • Case Study 10

Case Study 5

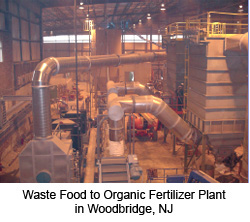

New Waste Food To Organic Fertilizer Plant Buys All Process Equipment from I-2/BPST

In 2009, Converted Organics built a new waste food to organic

fertilizer plant in Woodbridge, NJ. The organic fertilizer is sold

at premium price for golf courses around the tri-state area. The

chemical components in standard fertilizer kill the animals living

among the golf courses. Thus, the demand for organic fertilizers

is high with regard to turf building.

In 2009, Converted Organics built a new waste food to organic

fertilizer plant in Woodbridge, NJ. The organic fertilizer is sold

at premium price for golf courses around the tri-state area. The

chemical components in standard fertilizer kill the animals living

among the golf courses. Thus, the demand for organic fertilizers

is high with regard to turf building.

Since, 2005 a group of investors worked with I-2/BPST

engineers to select proper equipment appropriate for the

plant. I-2/BPST has supplied various clarifier tanks, Nedco

Infeed Conveyors, Witte Fluid Bed Dryer, KWS vertical Screw

Conveyors, Metalfab Feeders, Scott Continuous Blender, Fox

Eductor Pneumatic Conveying Systems, Dust Collectors,

Spiroflow Aero-Mechanical Conveyor and Express Scale

Packaging units. The Converted Organics plant produces dry

fertilizer at a rate of 5 tons/hr.

Case Study 6

Firmenich Awards I-2/BPST $5 Million+ for Complete New Caps Project

Firmenich is an European top notch flavoring

manufacturing company in NJ, they awarded a $5m+

order to I-2/BPST, Inc. to provide a complete dry flavor

handling IBC System, Spiroflow’s Aeromechanical

Conveying system, and Nedco’s finished product

packaging system.

Firmenich is an European top notch flavoring

manufacturing company in NJ, they awarded a $5m+

order to I-2/BPST, Inc. to provide a complete dry flavor

handling IBC System, Spiroflow’s Aeromechanical

Conveying system, and Nedco’s finished product

packaging system.

Firmenich ordered Custom Powdered System’s container

blending IBC (Intermediate Bulk Container) automated wash

system to handle dry flavor in their new plant of Newark,

NJ. Due to the fragile nature of the finished product, the

presence of an explosive volatile, and required and

complex conveying distances, a Spiroflow Aeromechanical

Conveying System was selected to convey the finished

product. Nedco’s complete finished Product Packaging

System included automated carton forming equipment, belt

conveyors, pouch filler,

cardboard box filling,

Bunting Metal Detecting

System, an automated carton

closer, taping machines and a

Tawi vacuum pelletizing

system.

Case Study 7

Sara Lee Installed Spiroflow Aeromechanical Conveyor System

To meet high production capacity and to reduce labor costs,

Sara-Lee is automating their plant operations. The old

process was to fill out the portable bins and manually move

them over to the packaging units.

To meet high production capacity and to reduce labor costs,

Sara-Lee is automating their plant operations. The old

process was to fill out the portable bins and manually move

them over to the packaging units.

The central engineering group at I-2/BPST worked closely

with Sara Lee to develop a complex Aero-Mechanical

conveying network system that could be used throughout the

plant to convery flavored coffee from various packaging unit

throughout the plant.

Since Sara-Lee could not tolerate product segregation or

degradation there was extensive testing performed proving

that the Aero-Mechanical conveyor can handle Sara Lee’s

product gently, and that The Spiroflow Aero-Mechanical

System does not

segregate of the

flavored coffee mix nor

causes product

degradation.

The complex conveyor

system has been in

operation for several

months and it reduces

product handling time

and cost, resulting in a considerably increased production

efficiency.

Case Study 8

I-2/BPST Inc. Offers Safe Products for Comax Customers

Comax Flavor Company purchased a Bunting Magnet and

Metal Detector Combination System. They installed them under

each ribbon blender to meet HACCP regulations. I-2/BPST

provided large Rare Earth Grate Magnets on top of the ribbon

blender (3ft by 4ft) bag dump stations. The operator dumps all

ingredients through these magnets and the mixed finished

product goes through the Bunting Inline Metal Detector unit

before packaging. The combination of grate magnets at the

inlet and the metal detection unit at the outlet requires minimum

head room and provides safe products for Comax customers.

Comax Flavor Company purchased a Bunting Magnet and

Metal Detector Combination System. They installed them under

each ribbon blender to meet HACCP regulations. I-2/BPST

provided large Rare Earth Grate Magnets on top of the ribbon

blender (3ft by 4ft) bag dump stations. The operator dumps all

ingredients through these magnets and the mixed finished

product goes through the Bunting Inline Metal Detector unit

before packaging. The combination of grate magnets at the

inlet and the metal detection unit at the outlet requires minimum

head room and provides safe products for Comax customers.

Comax also had

problems with their

air mixers which

were too low in

power and taking too

long to mix. For thick

flavors, the mixers

would not work at all.

I-2/BPST proposed a

6HP heavy duty air

motor with 1.5” thick shaft and its proprietary high flow double

mixing propellers to solve the problem.

![]()