Bulk Process Equipment, Bulk Solid Material Processing & Handling Equipment, Industrial Bulk Solids Material Handling Systems

|

Material Handling & Processing Equipment |

About Us | Material Handling Equipment | Solid Material Processing | Plant Services | Manufacturers | Equipment Photos | Clients | Case Studies | News | Contact Us | Home

Solid Material Processing - Bulk Solids Material Processing Solutions

I-2/BPST is a manufacturers' distributor of bulk solids material handling & processing equipment and systems. We provide consultation, equipment and installation of industrial bulk solids material handling systems. Our turnkey solutions will assist companies in implementing cost-saving and income-producing solutions for their bulk processing machinery and systems.Shown below are questions to consider when determining the best solution for your Solid Material Processing needs:

I. Considerations for picking the right conveyor system for your material:

1. Name of your material, or similar to: Flour, sand, sawdust etc.

1. Name of your material, or similar to: Flour, sand, sawdust etc.

2. Bulk density (not particle density) : Simple to determine. Get a measuring cup or any small, known-volume open container. Measure the empty weight of the container and filled weight of the container. Your Bulk Density is the difference of filled weight and empty weight divided by the volume of the container.

3. Flowability: Does the material flow well or does it stick to the wall?

4. Particle Size: This is the most difficult to determine. If you do not know, it is okay for the preliminary selection to use as reference a similar material. Just mention if the material is dusty fine powder or granular or large chunks .

II. Your Process, Your Choices:

1. Raw material: How does the incoming material come in the plant?

a. In 50lb. (or similar) bags or drums

b. In Bulk Bags/Super Sacks

c. By Truck or Railcar, to outside/inside storage silos

2. If you need to convey material to your process from any of the above sources, the following are your common choices:

a. Mechanical Conveying:

a. Mechanical Conveying:

- Screw Conveyor

- Flexible Screw Conveyor

- Belt Conveyor

- Bucket Elevator

- Vibratory Conveyor

- Aero-Mechanical Conveyor

b. Pneumatic Conveying

- Dilute Phase Conveying Pressure or vacuum system

- Dense Phase Conveying Pressure or vacuum system

c. Mechanical Dumper- Lift & Hoist System

III. Choice of equipment:

Depends on Material Characteristics or Process Requirements, and Previous Experience

1. When to choose pneumatic conveying:

- Long conveying distances

- Many sources feed the process and many destination points to be delivered.

- Simple System

- Low maintenance

2. How do I choose one mechanical conveyor over other?

a. Flexible Screw - Low budget, good material flow characteristics, frequent change of product, short distance (below 30 ft). Things to consider about flexible screw:

- Best for light duty and intermittent (rather than continuous) operation

- Product degradation-may break down particles

- Outer tube wears out over the time and goes into the product

- Easy cleaning

- Easy product change

b. If your budget allows and frequent cleaning is not required, Solid screw Conveyor will typically be more durable than Flexible Screw.

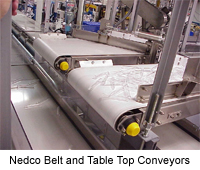

c. When do I use a Belt Conveyor?

- Can convey both wet and dry material of almost any size and shapes.

- Can convey very long distances

- Gentle handling of the product

- Needs more frequent maintenance and can be messier due to product spillage or if product is dusty

- To convey material Vertically up

- High maintenance equipment

- Messy in operation due to product leakage

3. How do I convey my product without significant product breakage?

Choices:

a. Belt, Vibratory, or Bucket Conveyor

Pros: Can handle most types of material. Widely used for handling, large, fragile material, especially for foods.

Cons: Dusty operation. Belt and bucket conveyors can be mess. Vibratory conveyors are limited by Length. Bucket Conveyors are expensive.

b. Aero-Mechanical Conveyor

Pros: Very low floor space requirement. For a straight run, it is very economical

Cons: Low system reliability

c. Pneumatic Conveying:

Pros: Conveys material to multiple destinations, large capacity, fairly long distances. Vacuum Conveying minimizes product leakage out of the conveying system.

Cons: Large investment, vacuum system usually limited to about 100 ft.